Glossary of Woodturning Terms: Lathe Parts

Banjo: This component mainly serves to support the toolrest. You can clamp the banjo in place anywhere along the lathe bed. Why is this part called a banjo? No one knows for sure; one common explanation is that early toolrest supports resembled the musical instrument.

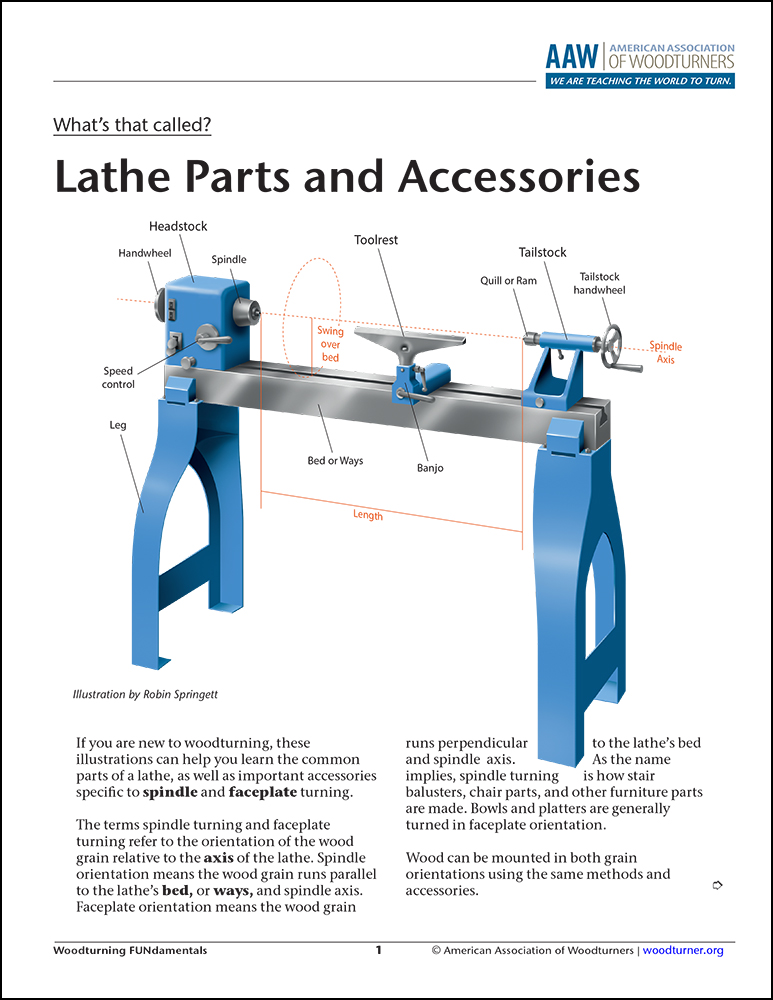

Bed/ways: The long, rigid, horizontal part of the lathe that supports the headstock, banjo, and tailstock.

Center: The general name for accessories that help hold a workpiece in place on the lathe. Drive centers, used in the headstock, have teeth that bite into the work. Live centers, used in the tailstock, have some sort of point at one end that engages the workpiece, and bearings that allow the pointed end to spin freely.

Chuck: The general name for accessories that grip a workpiece at the headstock. There are many different types of chucks, including scroll chucks, screw chucks, collet chucks, and pin chucks.

Collet Chuck: An accessory designed to hold a small tenon on a workpiece or the end of a dowel. Collet chucks typically grip pieces up to 1 inch in diameter in a split cylinder that is tightened around the workpiece with a threaded ring.

Speed Control: What you use to change the lathe speed. Some lathes have a set of stepped pulleys connected with a belt; shifting the belt to different pulleys changes the speed. Other lathes have electronic speed control, essentially a rheostat that changes the motor’s speed as you turn a knob.

Handwheel: A wheel on the headstock that helps you attach chucks, faceplates, and other accessories, and to rotate the workpiece by hand.

Headstock: The housing that contains the spindle and the spindle support bearings, as well as the belts and pulleys that transfer power from the motor to spin the workpiece.

Morse Taper: The term for the opening in a lathe’s headstock and tailstock, as well as for the shaft on accessories that fit in these openings. A Morse Taper is known as a locking taper, because the tapered opening holds the accessory securely; it generally must be tapped free with a long bar. There are three common sizes of Morse Taper. No. 1 is the smallest, generally used on older lathes. No. 2 is the most widely used today. No. 3 is the largest, used on some heavy-duty lathes.

Mandrel: a shaft or spindle secured in a lathe’s headstock, and used to hold small parts such as pen bodies in place while you turn them.

Motor: The lathe’s power source.

Pin Chuck: The name for a type of scroll chuck that has long, thin jaws. A pin chuck is intended to hold small workpieces.

Quill: The sleeve of a lathe tailstock in which the spindle is mounted.

Screw Chuck: An accessory that has a large screw protruding from a thick plate. You thread the screw onto the headstock spindle, then thread the workpiece onto the protruding screw.

Scroll Chuck: An accessory that has four self-centering jaws that grip a workpiece.

Spindle: The central portion of the lathe’s headstock and tailstock. The headstock spindle is threaded to accept chucks, faceplates, and other accessories, and it is bored with a Morse Taper. The tailstock spindle can be advanced or retracted with a handwheel and locked in place with a threaded lever. The tailstock spindle is also bored with a Morse taper.

Steady Rest: An accessory clamped to the lathe bed and used to support long, thin workpieces as a way of minimizing vibration.

Tailstock: A movable assembly mounted on the lathe bed that you use with various accessories to support the workpiece.

Tailstock Handwheel: A wheel with a handle that you use to move the quill by hand.

Tailstock Quill Lock: Used to lock the quill in place.

Toolrest: A T-shaped component. The vertical part of the toolrest is a thick rod that locks into a socket on the banjo. The horizontal part of the toolrest—typically straight, but also curved or S-shaped—supports the end of a woodturning tool. You can freely rotate, raise, or lower the toolrest and lock it in place with a clamp on the banjo.

Download Lathe Parts and Accessories Handout